Diesel truck collision repair is a specialized field requiring skilled technicians to address unique challenges of large vehicles. The process begins with a comprehensive inspection, followed by safe disassembly and meticulous repair focusing on structural integrity and key components like bumpers. Advanced techniques and tools, including welding, metal fabrication, and CAD software, are employed to restore performance and safety features. Safety and quality are paramount, with mechanics adhering to strict protocols and using top-tier equipment for precise alignment and seamless aesthetic restoration.

“In the realm of automotive restoration, diesel truck collision repair stands out as a specialized art. This comprehensive guide is tailored for professionals seeking to master the intricacies of this complex process. From understanding the unique challenges posed by diesel trucks post-collision to equipping yourself with essential tools and adhering to stringent safety protocols, each step is crucial in delivering top-tier repairs. By embracing best practices, mechanics can ensure the longevity and performance of these powerful vehicles.”

- Understanding Diesel Truck Collision Repair Process

- Essential Tools and Equipment for Efficient Repairs

- Safety Protocols and Best Practices for Professional Mechanics

Understanding Diesel Truck Collision Repair Process

Understanding Diesel Truck Collision Repair Process

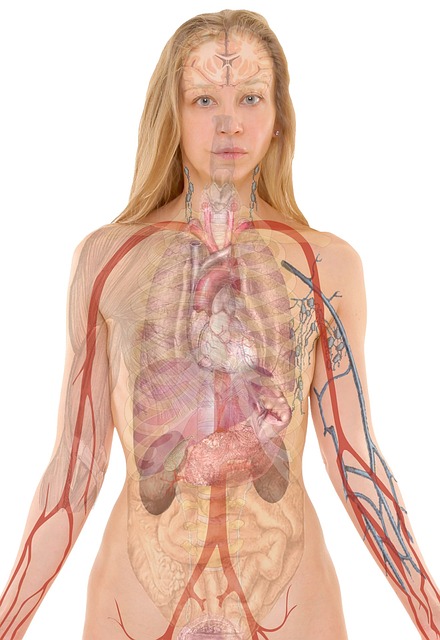

Diesel truck collision repair is a specialized field that requires skilled technicians to handle the unique challenges posed by these large vehicles. The process begins with a thorough inspection to assess the extent of damage, including components like the frame, engine, and various systems integral to the truck’s operation. Unlike smaller cars, diesel trucks often have robust frames and powerful engines, necessitating specialized equipment and expertise for safe disassembly and repair.

The repair itself involves a meticulous approach, focusing on not just visible damage but also underlying structural integrity. Key components such as the bumper, which serves both aesthetic and safety purposes, need careful attention during the collision repair process. In many cases, advanced techniques like welding, metal fabrication, and computer-aided design (CAD) software are employed to ensure precision and accuracy in rebuilding the truck to its pre-accident condition, or even enhancing it with improved performance and safety features.

Essential Tools and Equipment for Efficient Repairs

In the realm of diesel truck collision repair, professionals require a well-equipped arsenal to efficiently tackle complex repairs. Essential tools and equipment include specialized welding machines capable of handling heavy-duty steel, robust impact wrenches for swift and precise disassembly, and advanced diagnostic scanners to identify electronic issues unique to modern trucks. Additionally, high-quality auto body painting tools such as airbrushes and spray guns are crucial for achieving a seamless finish.

Beyond these, body shop services necessitate the use of specialized jigs and stands to secure the vehicle during repairs, along with precision measurement tools like calipers and laser measures to ensure exacting alignment. Efficient diesel truck collision repair hinges on having the right tools, making it imperative for professionals to invest in top-tier equipment that facilitates precise, safe, and swift restoration of these substantial vehicles to their pre-collision condition, focusing on both structural integrity and aesthetic appeal.

Safety Protocols and Best Practices for Professional Mechanics

In the high-stakes environment of diesel truck collision repair, safety protocols and best practices are non-negotiable. Professional mechanics must always prioritize their well-being and that of their colleagues. This includes wearing appropriate personal protective equipment (PPE), such as safety goggles, gloves, and respirators, to minimize exposure to hazardous materials and debris. Additionally, adhering to strict protocol when handling compressed air, heavy parts, and high-pressure fluids ensures the prevention of accidents and injuries.

Beyond individual safety, mechanics play a crucial role in ensuring the overall quality of diesel truck collision repair. This involves meticulous attention to detail during every step of the process, from initial assessment and disassembly to final reassembly and auto painting. Utilizing specialized tools designed for precision and accuracy, such as advanced welding equipment and state-of-the-art alignment systems, helps achieve flawless bumper repair and restoration. The ultimate goal is not just to return the vehicle to the road but to do so with unmatched craftsmanship that reflects the reputation of the auto body shop, fostering customer satisfaction and loyalty in the competitive market for diesel truck collision repair services.

Diele truck collision repair is a specialized field that requires a deep understanding of complex vehicle systems and a commitment to safety. By following the outlined process, utilizing essential tools, and adhering to best practices, professionals can ensure efficient repairs, minimize downtime, and maintain the high standards expected in the industry. With a focus on safety and expertise, diesel truck collision repair can be a seamless and effective process, keeping both vehicles and drivers on the road safely.